|

|

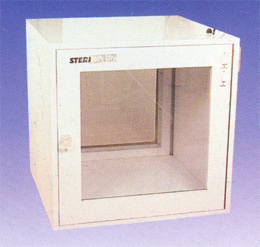

Pass

Box Pass

Box |

| |

|

DM–207

Stericlean Pass Box

Introduction Introduction

The pass box is an equipment normally installed on the wall between

the clean room and any other room. It is used for transfer of material

from and into the clean room, without contaminating the air of clean

room and without having to open room door. This is achieved with

the help of interlocking type doors of pass box.

Principal of Working

This equipment is installed on the wall between the clean room and

the other room. The pass box has two doors at its extreme ends.

One door opens in the clean room and other door open in the other

room. These doors are electrically interlocked type so that any

one door can be opened at a time. This avoids direct flow of air

from the clean room to the other room or vice versa. This also obviates

the need to open the clean room door frequently for transferring

of material from & into the clean room. Thus, it helps in achieving

the aim of material transfer without disturbing the cleanliness

level of the clean room.

Construction

It is made of Commercial board & all its external & internal surfaces

are dully laminated. L.M.S. or S.S. Sheet body also can be supplied

optionally. Each hinged door has wide glass viewing window, through

which material kept in the pass box can be seen. These doors are

electrically interlocked type, so that any one door can be opened

at a time. UV & fluorescent light and HEPA filter can be provided

optionally.

Size :– 24"(W) × 24"(H) × 24"(D).

Other sizes on request.

DM–208

Stericlean Pass Box with HEPA Filters (Class 100) (Filtered Air

Material Transfer Windows) (New)

Introduction Introduction

Pass box in an equipment used normally for transfer of material

from & into the clean room without contaminating the clean room

air & without opening the clean room door. The two opposite doors

are interlocked & only one door can be opened at a time. Fluorescent

light in automatically put ON at the time of opening nay one of

the doors. The doors have glass window for viewing the material

kept there in.

Salient Feature

It is specially designed equipment where in a HEPA filter has been

provided & the motor blower unit is automatically put ON at the

time of opening any of the doors. It thus act as a pressure chamber.

Only clean air can enter the clean room through pass box, because

clean air through HEPA filter is put ON immediately automatically

on opening any door. The clean room air is thus not contaminated

by the air of pass box.

Fluorescent light is provided for visibility of item kept in the

pass box & it is ON at the time of opening any of the door for taking

out or putting in the material in the pass box. UV light can be

optionally provided which will be put ON only on closing the door,

that is UV light will be permanently ON for sterilizing the material

kept in the pass box & it will be off at the time of opening the

door, so that human eye is not effected by UV light.Buzzer Switches

are provided on both doors to signal for material insertion/removal.

Construction

These are elegantly designed & manufactured from commercial board

& all external & internal surfaces are laminated. SS/Alum/MS sheet

duly powder coated body can optionally be supplied.

Power Requirement

Suitable to work on 220V, 1 ph, 50 Hz AC supply.

Size :– 24"(W) × 24"(H) × 24"(D).

Other sizes on request.

|

|

|

|

Copyright

© YORCO. All rights reserved.

|