|

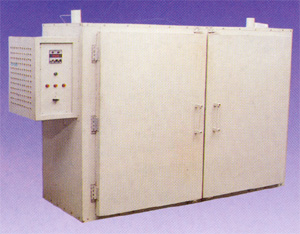

YSI–436

York Industrial Drying Oven

---High Temps

Suitable

for heat treatment, baking and drying applications in Industries

or Institutes engaged in the production of Vaccines. Tablets, Bottle

Sterilizing, Baking Breads or Biscuits, Drying Chemicals, PCB Processing,

Armature Windings, Soaking electronic components like Yoke, Coils,

EHT Coils, Transformers etc. Suitable

for heat treatment, baking and drying applications in Industries

or Institutes engaged in the production of Vaccines. Tablets, Bottle

Sterilizing, Baking Breads or Biscuits, Drying Chemicals, PCB Processing,

Armature Windings, Soaking electronic components like Yoke, Coils,

EHT Coils, Transformers etc.

Construction :– The construction is double walled on

sturdy angle iron frame with both inner and outer walls of thick

PCRC sheet which is duly pretreated for surface treatment &

finished with powder coated paint. The inner wall is painted with

high temp. aluminium paint to withstand long duration heating cycles

normally required in industrial applications, and the outer wall

is finished with powder coated paint. The 75 mm gap between the

two walls is filled with high grade glass wool insulation to prevent

loss of heat and thereby saving energy. Air is circulated by a heavy

duty blower to maintain inside temperature uniformity with a minimum

temperature gradient throughout the working chamber. Brackets to

support the heavily laden perforated trays at different height are

provided on the sides of the inner chamber. The front door with

sturdy hinges are also double-walled with gap between the two walls

filled-in with high grade glass wool insulation. The door also have

system to prevent opening.

Heating :– Heating is done by Tubular air heaters placed

in the moving air path. These are interlocked with blower. Ventilation

with adjustable opening on the top facilities fleeing of any fumes

or vapors produced during the process.

Temp. Control :– The temperature is controlled by fine

capillary hydraulic type imported thermostat with an accuracy of

5°C over a range of 50°C to 250°C ± 5°C.

Temperature is indicated by Dial Thermometer. The equipment is tested

for continuous performance & safe operation in out most modern

testing laboratory. It is securely packed to avoid any transit damage

during despatch.

Control Panel :– The Control panel include a Main switch

to ON/OFF the unit, mains indicator, a dial type thermometer, Temperature

control knob of thermostat is calibrated in the factory after actually

observing the temperature in steady state.

Power Supply :– The unit is supplied complete in all

respect. It is suitable to work on 220V, 50 Hz single phase or 440

V, three phase Ac depending upon the size.

Optional Accessories :–

• Timer

• Digital Indictor in lieu of dial thermometer.

• Temperature Indicator cum Controller Digital in lieu of thermostat

& dial thermometer.

Size of inner chamber :–

W × H × D Tray Cap. Load

90 × 90 × 60 cms (3´ × 3´ ×

2´) 12 5 KW

90 × 90 × 90 cms (3´ × 3´ ×

3´) 18 6 KW

90 × 120 × 90 cms (3´ × 4´ ×

3´) 24 7 KW

90 × 150 × 90 cms (3´ × 5´ ×

3´) 24 10 KW

90 × 180 × 60 cms (3´ × 6´ ×

2´) 36 10 KW

90 × 180 × 90 cms (3´ × 6´ ×

3´) 48 15 KW

90 × 240 × 90 cms (3´ × 8´ ×

3´) 60 15 KW

120 × 240 × 90 cms (4´ × 8´ ×

3´) 96 18 KW

120 × 180 × 120 cms (4´ × 6´×

4´) 48 18 KW

YSI–436T

York Tray Dryer

Same

as YSI-436 but with aluminium trays & M.S. Trolley. Same

as YSI-436 but with aluminium trays & M.S. Trolley.

Size of Inner chamber :–

W × H × D

Tray

Load

430 × 840 × 915 mm 12

4 kw

915 × 840 × 915 mm 24

6 kw

965 × 1275 × 1450 mm 48

10 kw

965 × 1700 × 1700 mm 96

20 kw

|